Drop forged chains

Designed and manufactured to ensure optimal performance even in particularly hostile environments and in the presence of abrasive agents and high operating loads.

Reliable even under extreme conditions, Sircatene forged chains are used in many industrial sectors for conveying materials. Designed to work with heavy loads, they are resistant to wear and chemical agents.

Over the years, Sircatene has developed significant know-how in manufacturing forged chains and so cutting-edge production and technological plants within a production facility are dedicated exclusively to it.

The use of welding robots and qualified staff ensure accurate execution, mechanical quality well above standard and consistent performance over time.

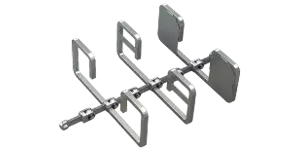

Scraper chains with forged links

Scraper chains with standard forged links

Scraper chains with standard-type forged links. Standard materials: C43, 20MnCr5, 18NiCrMo5. Other materials on request

Scraper chains with standard forged links

Scraper chains with standard-type forged links. Standard materials: C43, 20MnCr5, 18NiCrMo5. Other materials on request

Scrapers for chains with pressed links

Scrapers for chains with pressed links: square, flat, bent, “U” bent, “C” bent, “Double O”, “C” bent reinforced, “K” bent reinforced, for dual chain, “Double O” forged and special attachments

Scrapers for chains with pressed links

Scrapers for chains with pressed links: square, flat, bent, “U” bent, “C” bent, “Double O”, “C” bent reinforced, “K” bent reinforced, for dual chain, “Double O” forged and special attachments

Drive and reverse sprockets for scraper chains with standard pressed links

Drive sprockets with diameters from 216 mm to 710 mm for series R100201, R100202, R100203, R100204, R100205, R100206, R100207, R100208, R100209, R100210, R100211.

Drive and reverse sprockets for scraper chains with standard pressed links

Drive sprockets with diameters from 216 mm to 710 mm for series R100201, R100202, R100203, R100204, R100205, R100206, R100207, R100208, R100209, R100210, R100211.

Reverse wheels

Reverse wheels with diameters from 160 mm to 610 mm for series R100301, R100302, R100303, R100304, R100305, R100306, R100307, R100308, R100309, R100310, R1003

Reverse wheels

Reverse wheels with diameters from 160 mm to 610 mm for series R100301, R100302, R100303, R100304, R100305, R100306, R100307, R100308, R100309, R100310, R1003